Need help designing your VAV diffuser system?

SYSTEM DESIGN

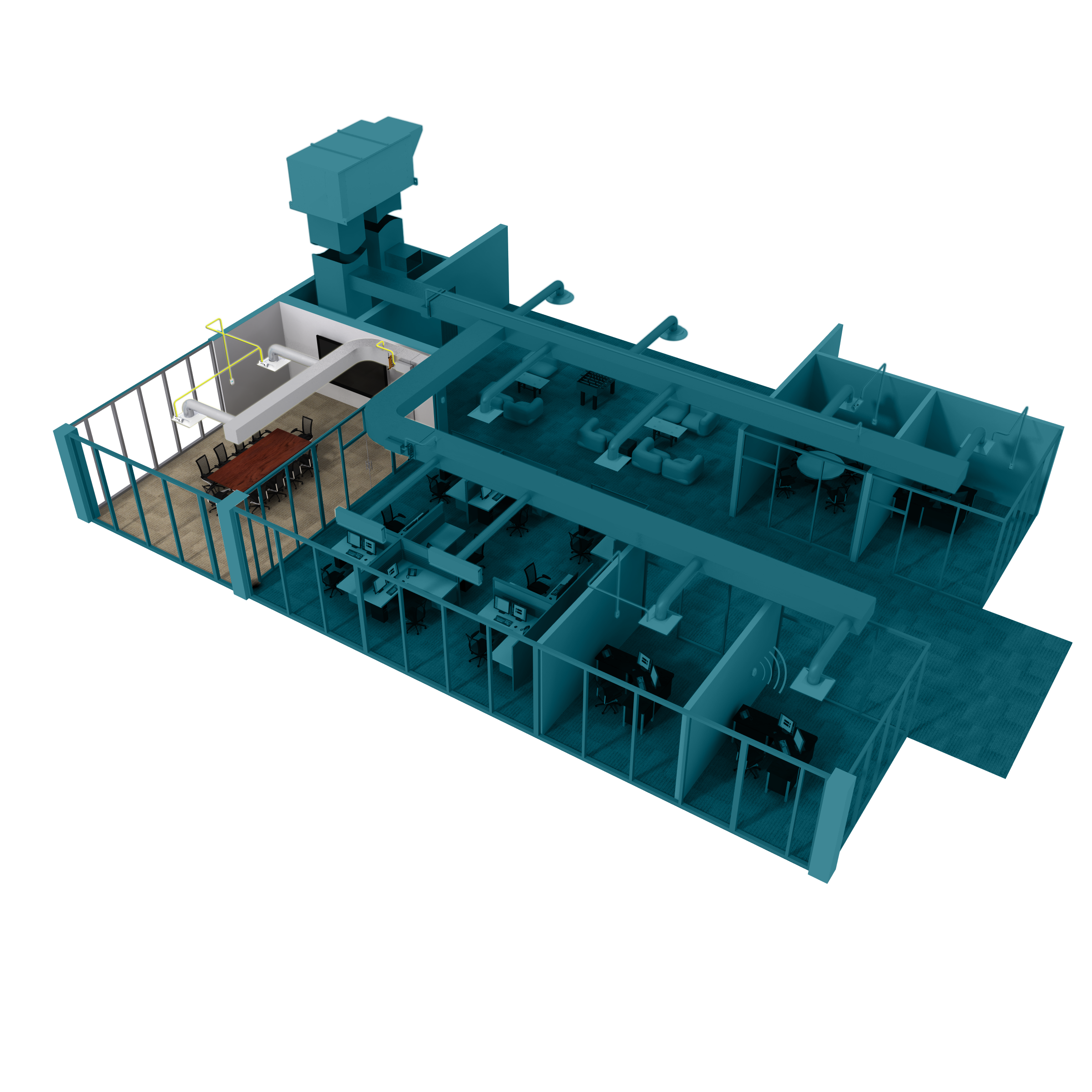

Sustainable, efficient and modern system design requires a combination of contemporary design approaches and leading-edge products and technology.

A comfortable environment is achieved by providing the smallest possible zones of temperature control, allowing for individual temperature distribution and better air movement. Reduction in energy is realized by designing a low-pressure HVAC system that allows for maximum turndown, while maintaining temperatures.

Acutherm by Price’s VAV diffusers are available in mechanical thermal actuation (Therma-Fuser Series), and digital electric actuation, (Advantage and Interoperable Series’). These can be configured to achieve a high-performance air system.

SUPPLY AIR TEMPERATURE

Acutherm by Price VAV diffusers are simple stand-alone devices that provide VAV control when supplied with air in a suitable range of temperature and pressure.

When supplied with cool air, the dampers modulate open on a rise in room temperature. When supplied with warm air, the dampers open on a room temperature drop.

Cool air should be a constant temperature not less than 50°F/10°C for standard models (40°F/4.5°C for model LT-HC) and warm air at a constant temperature of not more than 120°F/49°C. The constant discharge velocity of these diffusers at varying air flow provides good room circulation which reduces stratification. Keeping heating supply air temperatures as low as possible will further reduce room air stratification to a negligible level.

Changeover from cooling to heating occurs as the supply air rises from 76°F/24.5°C to 80°F/26.5°C and change back from heating to cooling occurs when the supply air drops from 72°F/22°C to 68°F/20°C.

WHAT IT NEEDS

Supply Air Temperature

-

Constant temperature. May be reset to another constant temperature.

-

Cooling between 50°F/10°C and 68°F/20°C.

-

Heating between 80°F/26.5°C and as low as possible, but not to exceed 120°F/49°C.

Static Pressure

-

High enough for required air volume. No lower than 0.05”wg/12Pa.

-

Below rated static pressure for design sound level. No higher than 0.25”wg/62Pa suggested.

Design Resources

Energy and Sustainability

Energy Modeling Guide for Therma-Fuser Systems

Sustainable Design Guide (LEED)

Recommendations for Low Energy VAV Systems

AMCA High Performance Air Systems

Comparing Energy Savings of Different VAV Systems

General Design Guides

Designing Therma-Fuser VAV Systems

Essentials of a Modular VAV System

Options of Static Pressure Control and Pressure Independence

Specific System Design Guides

Constant Volume DX Units Including Heat Pumps

Air Handling and Fan Coil Units

“Texas Multizone Zones” System

STATIC PRESSURE

Noise level at any air diffuser is influenced by air velocity through the diffuser. In turn, air velocity is a function of static pressure in the neck of the diffuser. Noise level at a VAV diffuser will not increase as it closes if the static pressure in the neck is held constant. As static pressure in the neck increases, sound level increases.

Static pressure at the inlet of a VAV diffuser must be high enough (0.05”wg /12 Pa or more) to obtain the required air volume for room air induction. Static pressure above 0.25”wg/62 Pa may cause the sound level to become noticeable (NC35). When the static pressure is held constant, the sound level will decrease as the dampers close.

LOCATION AND SIZING

Because Therma-Fuser diffusers control room temperature by sensing room air induced up the center of the space, care should be taken not to disturb room air induction and entrainment. For example, location next to walls or dropped lights results in the reflection of primary air back at the Therma-Fuser diffuser. Relocate either the Therma-Fuser diffuser or the light.

Therma-Fuser diffusers are sized for the design or maximum air volume required using the published performance guide. Use a larger inlet size at a lower static pressure when lower sound or NC levels are required and when Therma-Fuser diffusers are at the end of a duct run where less static pressure is available.

Therma-Fuser diffusers may be oversized. They will simply turndown air flow to match the space load. Unlike fixed diffusers used with VAV boxes, Therma-Fuser diffusers won’t dump when turned down.

DUCT DESIGN

The goal of a high performance duct design is to design for lowest possible static pressure while providing ample air to each space.

Duct design example: if Therma-Fuser diffusers are to deliver nominal volume at inlet SP of 0.15”wg / 37Pa and if a maximum SP of 0.25”wg / 62Pa is to be held for quiet operation, size the duct for a maximum pressure drop of 0.1”wg /25 Pa between the first and last takeoff.

Manual balancing dampers should be used at the takeoff for each diffuser. Manual balancing dampers may not be required with ducts designed to Acutherm specifications.